Company news

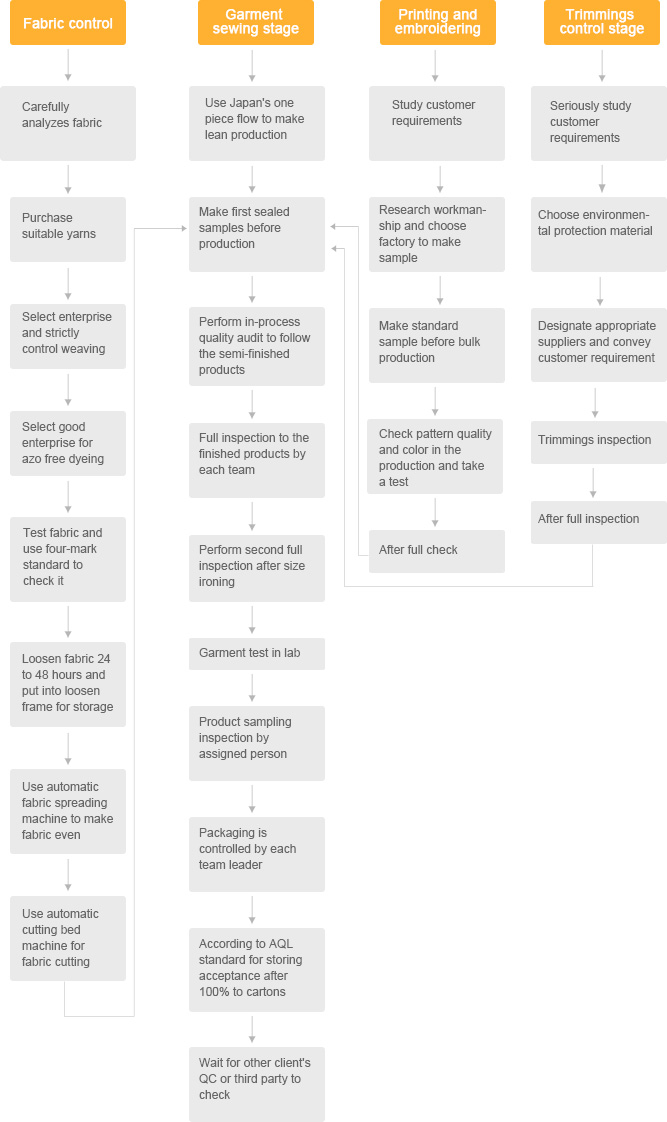

Our whole procedure of quality assurance

1. Fabric control:

Before receive orders we carefully analyzes fabric to ensure whether it is suitable for bulk production or not and prevent problems that may arise in bulk production process.

We select good enterprise for dyeing, before dyeing azo free dyeing is required. After the fabric dyeing is ended, we check color fastness, shrinkage rate and other internal index test according to the customers' fabric requirement. After passing inspection standard we check fabric with 4-mark standard, then put very roll of fabric to loosen machine, afterwards put the fabric into the loosen frame for storage.

Loosen 24 to 48 hours according to the characteristics of fabrics and go to cutting room. Loosen fabric mainly is to reduce the tension of fabrics, make the fabric tension back to nature and effectively guarantee the stability of the garment sizes.

In the cutting room, our company is equipped with an automatic fabric spreading machine to avoid the problem of uneven fabric elastic effectively. We spread the fabric according to the provisions to ensure that the fabric do not exceed the specified height. Automatic cutting bed machine is used for fabric cutting after finish spreading to ensure the accuracy of the cuttings and the final stability of the garment.

2. Garment sewing stage:

We use Japan's one piece flow of lean production, ensure the piece to flow into and the garment comes out in the same day, control quality effectively and detect problem timely. Before production each team has to make first sealed samples and hold a meeting. After pre-production training then begin to garments sewing production.

During garment finished, thread clean machine, fusing machine, ironing machine (ironed by the given size) are used to make clean and even.

We have line inspectors in every sewing team to follow the semi-finished products, team inspector is committed to make full inspection after sewing , and then begin second full inspection and specially assigned person is responsible for product sampling inspection.

After qualified then begin to packing which is controlled by the team leader. According to the customers' requirement AQL standard for storing acceptance on the condition that 100% to cartons. Then wait for customer's QC or third party to check.

During the time we have to send the finished product to the lab or to the third party laboratory for out layer and color fastness testing so as to make sure the garment inner quality is better.

3. Printing and embroidering stage:

Before print and embroidery, we study the customer requirements and choose the factory with corresponding performance price ratio to make sample.

Before making sample, we research workmanship demands and communicate with factory staff timely to avoid repeated proofing. We endeavor to make sample on one time so as to improve the efficiency and reduce the waste of resources.

Standard sample is finished before bulk production, then check pattern quality and color in the production, check whether the production is according to the standard process and production workmanship, and take a test of color fastness and washing fastness. After all specifications are qualified then begin to garment matching production.

4. Trimmings control stage:

Designate appropriate suppliers according to customer request.

Seriously study and convey customer requirements to trimmings suppliers.

Select environmental material and test trimmings for garment production.